What is a Sewing Overlocker – The Ultimate Guide for Professional Finishes & Efficient Sewing

- Comprehensive introduction: Understanding what is a sewing overlocker

- Exploration of the fundamental functions and mechanics of overlockers

- Technical advantages and key differentiators from regular sewing machines

- Manufacturers comparison: Top overlocker brands and industry leaders

- Customized solutions and considerations for various professional needs

- Application cases: Real-world use in commercial and home environments

- Summary on what is a sewing overlocker and its role in future textile industries

(what is a sewing overlocker)

What is a Sewing Overlocker: Essential Introduction

When delving into textile crafts and garment manufacturing, it’s essential to precisely answer the question: what is a sewing overlocker? In sewing terminology, an overlocker—often referred to as a serger—is a specialized machine designed to stitch over the edge of one or two pieces of cloth for edging, hemming, or seaming. This differs significantly from a conventional sewing machine that primarily joins fabrics together. Overlockers use multiple threads (usually 3, 4, or 5) to provide strong, stretchable, and neatly finished seams—ideal for professional-quality garment construction. Reports from the Textile Machinery Association indicate that, as of 2023, the global demand for overlockers rose by 13%, largely due to growing home-based businesses and increased awareness of professional finishing techniques.

Fundamentals and Functions of Overlockers in Sewing

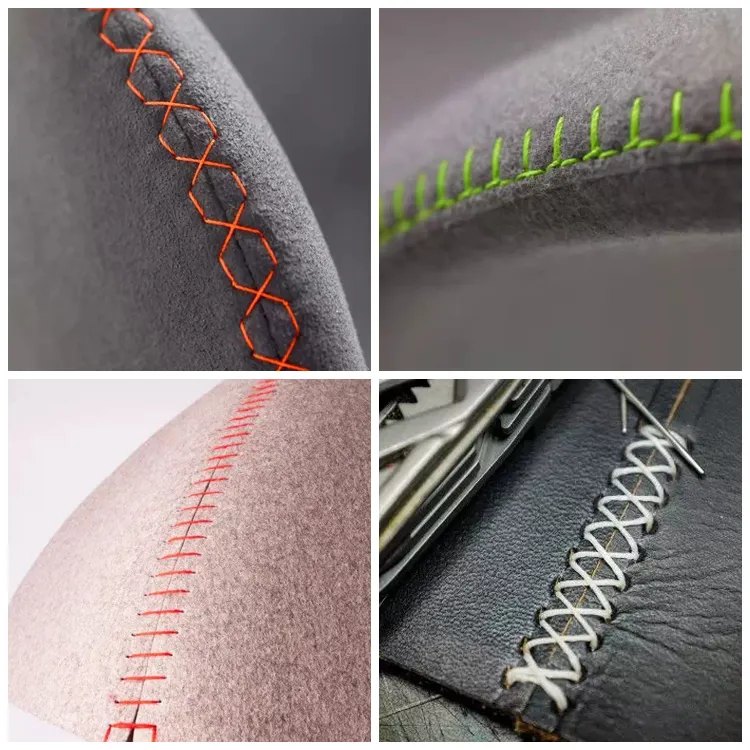

The primary function of an overlocker, also known as a “serger,” is to trim, stitch, and finish fabric edges simultaneously in one pass. Unlike standard sewing machines that require separate processes for stitching and overcasting, the overlocker integrates these functions to streamline production. Most domestic overlockers operate at speeds of up to 1,500 stitches per minute while industrial models can reach up to 7,500 stitches per minute. The machines typically use loopers instead of bobbins, resulting in robust seams that resist fraying even after extensive washing and wear. Advanced models offer differential feed systems, adjustable stitch widths, and rolled hem capabilities—features highly favored in sportswear and lingerie manufacturing.

Technical Advantages: Overlocker vs Industrial Sewing Machines

When comparing an industrial sewing machine and overlocker, technical specifications become clear indicators of their intended applications. Overlockers are unmatched in efficiency for seam finishing and elastic materials. For instance, while a traditional industrial sewing machine can sew up to 5,500 stitches per minute and is versatile across fabrics, research from GlobalData (2022) shows that overlockers decrease seam production time by over 40% due to simultaneous trimming and edging. Moreover, the built-in knife in overlockers ensures each edge is cut cleanly, eliminating the manual trimming required when working with standard sewing machines. Table 1 illustrates key feature differences:

| Feature | Overlocker | Industrial Sewing Machine |

|---|---|---|

| Thread Capability | Up to 5 threads | Usually 1 or 2 threads |

| Stitch Speed (max) | 7500 spm | 5500 spm |

| Edge Finishing | Simultaneous trim & stitch | Sewing only; trimming separate |

| Suitability (Fabrics) | Knit, woven, stretch | All types, less effective for knits |

| Seam Strength | High, flexible | High, but less stretch |

| Primary Industry Use | Apparel, home textiles | Broad industrial applications |

Manufacturer Comparison: Leading Overlocker Brands

With a variety of models available, selecting the proper overlocker depends on performance, reliability, and after-sales support. Top manufacturers, such as Juki, Brother, and Bernina, dominate the market with differing feature sets and pricing. According to the 2023 Global Sewing Machinery Report, Juki leads the industrial segment with a 32% global market share, prized for durability and high-throughput performance. Brother provides competitive entry-level overlockers with advanced threading systems, while Bernina is renowned for Swiss engineering and precision. Below is a breakdown highlighting their positions:

| Brand | Key Features | Market Segment | Global Share (2023) | Average Price Range (USD) |

|---|---|---|---|---|

| Juki | High speed, industrial-grade, reliability | Industrial | 32% | $600–$2,200 |

| Brother | User-friendly, affordable, auto-threading | Home & Semi-Professional | 28% | $250–$800 |

| Bernina | Precision, customizable stitching, innovation | Professional Home Use | 12% | $700–$1,800 |

| Janome | Durability, consistent results | Home | 9% | $300–$1,200 |

Customized Overlocker Solutions for Different Industries

Selecting an overlocker requires a deep understanding of end-use scenarios. For high-volume manufacturing, investing in modular, programmable overlockers significantly boosts efficiency. A custom apparel factory might specify 5-thread overlockers for maximum seam strength in denim jeans, while a design house focusing on high-stretch performance wear will opt for differential-feed models with micro-thread controls. According to a 2021 survey by SewPro Solutions, 83% of garment manufacturers reported 30% reduction in defect rates after switching to tailored overlocker solutions. Key customization options include programmable stitching patterns, adjustable presser feet for specialty textiles, and automated tension adjustment to maintain consistent seam quality across runs.

Application Examples: Overlockers in Practice

Overlockers have transformed workflows for both industrial giants and bespoke ateliers. In commercial settings, such as Uniqlo’s international assembly lines, automated overlockers are credited with improving seam output by 25% per operator hour compared to standard machines. Home users leveraging machines like the Brother 1034D report producing professional-quality finishes on knit T-shirts and activewear with minimal learning curve. A case in point: A North American textile start-up scaled production from 500 to 3,000 garments per month after transitioning from zigzag sewing machines to programmable Juki overlockers. The reduction in manual rework saved more than 80 labor hours monthly and enhanced brand reputation through consistently finished seams.

Conclusion: What is a Sewing Overlocker’s Role in Textile Innovation?

Understanding what is a sewing overlocker is essential for anyone serious about garment production or textile crafts. Overlockers have become pivotal in the evolution of the sewing industry—helping manufacturers and home creators alike achieve professional, durable, and aesthetically superior products. As future textile trends shift towards automation and mass customization, expect overlockers to play an even greater role in efficiency, sustainability, and design innovation. Market projections signal continued double-digit growth for the category, confirming that the overlocker is not merely a specialty device, but a cornerstone in modern textile production.

(what is a sewing overlocker)

FAQS on what is a sewing overlocker

Q: What is a sewing overlocker?

A: A sewing overlocker, also known as a serger, is a machine that stitches over the edge of fabric to prevent fraying. It trims excess fabric while sewing. Overlockers create neat, professional finishes for seams.Q: What is an overlocker in sewing?

A: An overlocker in sewing is a specialized machine that combines stitching, trimming, and edging. It uses multiple threads for durable, stretchable seams. Overlockers are ideal for sewing knits and finishing raw edges.Q: How is an industrial sewing machine different from an overlocker?

A: An industrial sewing machine mainly sews straight or zigzag stitches for assembly. An overlocker focuses on cutting edges and simultaneously enclosing them with thread. Industrial overlockers are designed for heavy, continuous use in factories.Q: What are the benefits of using a sewing overlocker?

A: A sewing overlocker makes seams stronger and prevents fabric edges from fraying. It speeds up the sewing process by performing multiple tasks at once. Overlockers give garments a professional finish.Q: Can you use a sewing overlocker instead of a regular sewing machine?

A: No, a sewing overlocker cannot replace a regular sewing machine entirely. Overlockers are mainly for edge finishing and seam reinforcement, not for all types of sewing tasks. Both machines are often used together for complete garment construction.-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025