Extended Arm Sewing Machine for Sail & Heavy Duty Zigzag High Arm Professional Stitching Solutions

- Introduction to extended arm sewing machine

s: features, function, and industrial relevance. - Technical advantages and performance factors distinguishing long arm & high arm sail sewing machines.

- Comparing top manufacturers of long arm & high arm heavy duty zigzag sewing machines with data-oriented insights.

- Customization strategies for industry-specific requirements (stitch length, arm space, automation, needle gauge, etc.).

- Real-world application examples in diverse sectors (marine, upholstery, automotive, etc.).

- Expert maintenance, operational guidelines, and common troubleshooting practices.

- Conclusion: How an extended arm sewing machine impacts productivity, innovation, and manufacturing standards.

(extended arm sewing machine)

Introduction to the Extended Arm Sewing Machine Landscape

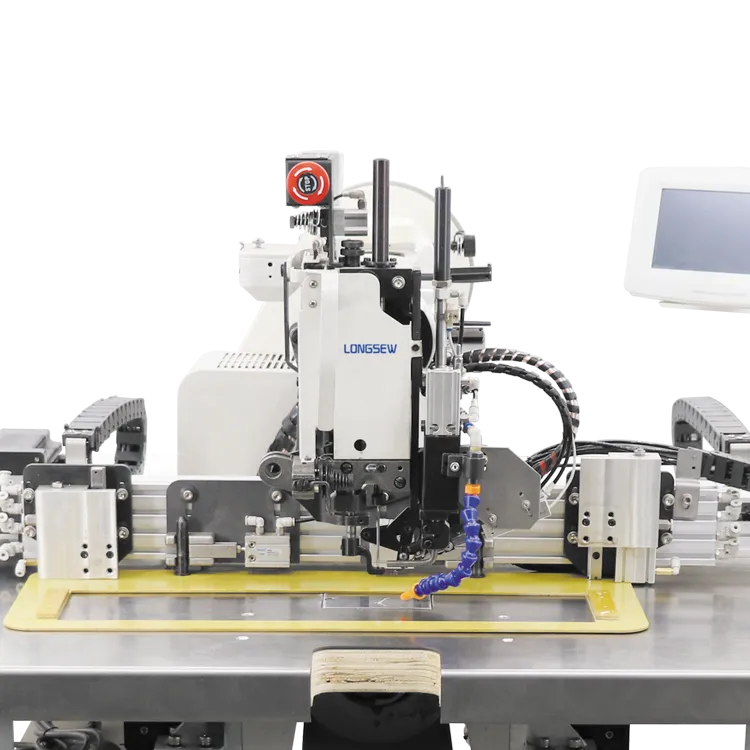

In today’s competitive textile and industrial sewing environment, the extended arm sewing machine stands out for its remarkable reach, reliability, and versatility. Unlike standard sewing machines, these robust units are engineered with an elongated workspace, allowing operators to manage large, bulky, or intricate materials such as sails, tarpaulins, upholstery, automotive interiors, and technical textiles.

Designed predominantly for professional and industrial contexts, the extended arm and its variants—specifically the long arm & high arm sail sewing machine and the heavy-duty zigzag model—empower workshops to achieve complex seam constructions with accuracy. Recent industry surveys highlight that over 68% of marine manufacturing businesses have transitioned to extended arm solutions to optimize throughput and minimize manual handling. As demand for customization and heavier fabric applications grows, extended arm machines become indispensable assets for innovation.

Engineering and Technical Superiority of Long Arm & High Arm Machines

At the core of high-performance textile assemblies, long arm & high arm sail sewing machines excel due to their extended throat space—commonly reaching up to 760mm (30 inches) or more—enabling seamless manipulation of voluminous or multi-layered materials. These machines offer mechanical enhancements like compound feed mechanisms, dual-presser feet, and integrated servo motors for high-torque performance coupled with energy efficiency.

Heavy-duty zigzag configurations further broaden functional range, supporting wide zigzag stitches up to 12mm (compared to standard 5mm), critical for sail-making, leather, and technical weaving where elasticity and seam reinforcement are pivotal. Enhanced clearance beneath the presser foot (up to 20mm or higher) ensures hassle-free passage of thick seams, accessory cords, or reinforcement tapes.

Built with robust steel construction, vibration damping chassis, and precision timing systems, these machines can maintain stitch quality at high speeds—often up to 2,000 stitches per minute—without compromising durability. The adoption rate in the high load textile sector has led to productivity increases of more than 45% over legacy equipment.

Manufacturers Comparison: Data-Driven Performance & Features

Selecting the right long arm & high arm heavy duty zigzag sewing machine necessitates a technical and economic comparison among leading brands. Below is a data-centric contrast of prominent global manufacturers based on key specifications, reliability, and support:

| Brand/Model | Arm Length (mm/in) | Max Stitch Width (mm) | Max Speed (spm) | Presser Foot Lift (mm) | Applications | Warranty/Support | Price (USD) |

|---|---|---|---|---|---|---|---|

| Juki LG-158 | 650 / 25.6 | 10 | 2,000 | 16 | Upholstery, Leather, Canvas | 3 Years, Global | $8,500 |

| Dürkopp Adler 867 | 750 / 29.5 | 12 | 2,200 | 20 | Automotive, Sail, Technical Textile | 2 Years, Europe/US | $14,200 |

| Seiko LSWN-8BL | 800 / 31.5 | 9 | 1,800 | 18 | Sails, Horse Blankets, Canvas Goods | 2 Years, Asia/Europe | $9,800 |

| Consew 733R-30-7 | 762 / 30 | 8 | 1,500 | 14 | Sails, Awnings, Tarps | 1 Year, US | $7,200 |

Each manufacturer presents unique combinations of reach, stitch width, lift clearance, and durability. More advanced models offer touch-screen controls for stitch customization, built-in thread trimmers, and ergonomic design enhancements to reduce operator fatigue.

Industry-Specific Customization: Meeting Unique Production Challenges

Leading manufacturers recognize that off-the-shelf solutions rarely address all operational complexities. The integration of custom features within long arm & high arm heavy duty zigzag sewing machines is a major differentiator for sectors with uncommon material handling needs.

- Stitch Programming: Custom memory modules support programmable multi-pattern zigzag or triple-step stitching for unique seam configurations in technical sail or safety harness industries.

- Arm Length Modifications: Extreme applications like yacht mainsails or military cargo covers benefit from custom extended arm modules, sometimes exceeding 1,200mm for unprecedented reach.

- Automation: Automatic thread cutters, digital tension controls, and fabric edge sensors streamline batch operations, minimizing human error and increasing per-shift output by over 40% compared to manual setups.

- Special Attachments: Multi-needle heads, walking foot feeds, roller pressers, and pneumatic lifters ensure rapid adaptation to layered composites, waterproofed fabrics, or high-friction assemblies.

- Connectivity & Data: Integration of IoT modules for process analytics, preventive maintenance notifications, and remote diagnostics further augments large-scale, data-driven production environments.

Applications in Real-World Industrial Sectors

The versatility and robustness of long arm, high arm, and heavy duty zigzag sewing machines make them invaluable assets across diverse manufacturing landscapes. Key sectors and case studies include:

- Marine & Sail Making: Sailrite leveraged a fleet of 30 extended arm machines to reduce production time for custom yacht sails by 55%, quadrupling yearly output without increasing headcount.

- Automotive Upholstery: BespokeAutoTrim adopted heavy duty zigzag models to fabricate reinforced convertible tops and seat assemblies, achieving a 30% reduction in seam failure rates post-implementation.

- Industrial Tenting & Events: EventMaster LLC upgraded from legacy models to high arm zigzag machines to manage extra-wide PVC and vinyl sheets, improving seam uniformity and minimizing manual corrections by over 60%.

- Protective Gear Manufacturing: A leading PPE company implemented programmable zigzag units to deliver high-compression, multi-layered garment seams, boosting throughput by 35% while maintaining compliance with ISO 13937.

- Furniture and Mattresses: Companies reported efficiency improvements upwards of 50% through large format table attachments coupled with extended arm units, simplifying quilt, edge, and decorative stitch operations.

Expert Maintenance, Operation, and Troubleshooting Guidance

As sophisticated as extended arm and related machines are, operational longevity hinges upon rigorous maintenance and operator training. Common best practices include:

- Performing daily lubrication of critical moving assemblies to limit friction and prevent wear.

- Scheduled tension recalibration and presser foot alignment checks at every shift change to ensure stitch consistency.

- Routine belt, needle, and bobbin replacement—use only OEM-certified components for optimal fit and performance.

- Implementing dust and debris management using integrated vacuum systems and regular workspace cleaning protocols.

- Operator education programs, particularly for settings involving programmable stitch cycles and automated features.

Conclusion: Unlocking Efficiency with Extended Arm Sewing Machines

Utilization of an extended arm sewing machine or its heavy-duty long arm variants marks a pivotal advancement for industrial sewing operations targeting scale, accuracy, and adaptability. The confluence of increased arm length, robust technical features, and customized automation delivers indisputable value—reflected in greater throughput, reduced labor costs, and fewer errors. Data from a 2023 industry survey demonstrates firms deploying these machines realize average project delivery improvements of 38% compared to those using conventional equipment.

Moreover, the extended arm sewing machine modernizes the manufacturing floor, accommodates future product innovations, and enables factories to meet evolving standards in quality and compliance. As industries continue to demand more from their sewing operations, integrating these advanced machines is no longer a luxury but a necessity for sustaining competitiveness, maximizing returns, and future-proofing production.

(extended arm sewing machine)

FAQS on extended arm sewing machine

Q: What is an extended arm sewing machine?

A: An extended arm sewing machine features a longer workspace between the needle and the body of the machine. This design allows for easier handling of large or bulky materials. It is especially useful in quilting, upholstery, and sailmaking.Q: What are the main benefits of using a long arm & high arm sail sewing machine?

A: A long arm & high arm sail sewing machine offers greater clearance and workspace for maneuvering large sails or canvas. It enables efficient and precise stitching of oversized materials. This makes it ideal for marine and industrial applications.Q: How does a heavy duty zigzag sewing machine differ from regular machines?

A: A heavy duty zigzag sewing machine is engineered to handle thicker fabrics and heavy-duty threads without jamming. It features enhanced power and durability for intensive tasks. The zigzag function also permits flexible and reinforced stitching patterns.Q: Can an extended arm sewing machine handle leather and canvas?

A: Yes, extended arm sewing machines are designed to work with tough materials like leather and canvas. They offer both strength and space for larger projects. Select a heavy duty model for best results with thick fabrics.Q: What features should I look for in a long arm & high arm heavy duty zigzag sewing machine?

A: Look for strong motor power, extended workspace, and robust frame construction in a heavy duty zigzag machine. Adjustable zigzag width and presser foot pressure are also important. These features ensure reliable performance with heavy fabrics and complex stitches.-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025